Titanium Oxide Nanoparticles have gained significant attention due to their unique properties and potential applications in various industries. These tiny particles, often referred to as TiO2 nanoparticles, have promising properties such as high surface area, photocatalytic activity, and biocompatibility. However, when working with Titanium Oxide Nanoparticles, it’s crucial to prioritize safety. In this comprehensive blog, we will explore in detail the safety regulations and guidelines to ensure the safe handling of Titanium Oxide Nanoparticles.

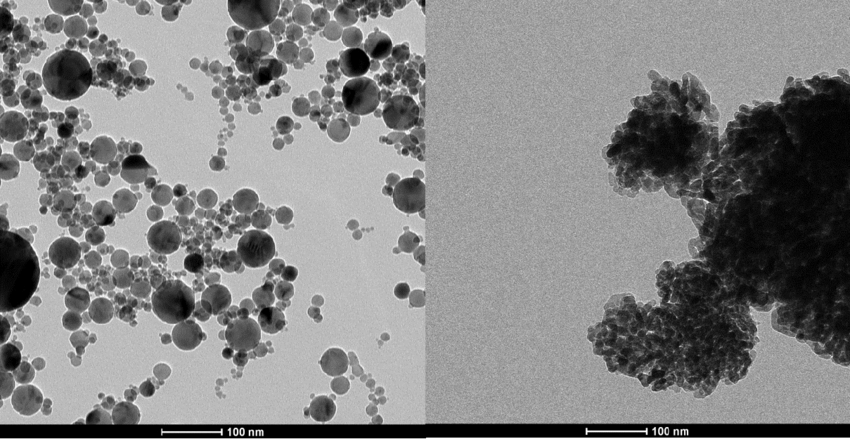

These nanoparticles are a form of titanium dioxide with a particle size typically less than 100 nanometers. They are widely used in various fields, including cosmetics, electronics, energy, and healthcare, owing to their unique properties.

Unique Properties of TiO2 Nanoparticles

Titanium Oxide Nanoparticles possess several unique properties that make them attractive for various applications:

- High Surface Area: TiO2 nanoparticles have an exceptionally high surface area, which enhances their reactivity and makes them useful in catalysis and surface modification.

- Photocatalytic Activity: They exhibit photocatalytic activity, meaning they can facilitate chemical reactions when exposed to light, opening doors to applications in solar energy and pollution remediation.

- Biocompatibility: TiO2 nanoparticles are generally considered biocompatible, making them suitable for biomedical applications such as drug delivery and imaging.

- UV Absorption: They have strong ultraviolet (UV) absorption capabilities, making them valuable in sunscreens and UV-blocking coatings.

Potential Hazards

While Titanium Oxide Nanoparticles offer immense potential, they also pose potential hazards to human health and the environment if not handled correctly. It is essential to have a comprehensive understanding of these hazards to implement effective safety measures. Here are some of the key hazards:

- Inhalation Risk: Inhalation of airborne TiO2 nanoparticles can lead to respiratory issues and lung damage. This risk is particularly significant in workplaces where nanoparticles are handled.

- Skin Exposure: Direct contact with the skin can cause skin irritation. It’s crucial to prevent skin contact through the use of appropriate personal protective equipment (PPE).

- Eye Irritation: Contact with the eyes may result in irritation and damage. Eye protection is vital when working with TiO2 nanoparticles.

- Environmental Impact: Improper disposal can harm the environment due to the persistence of nanoparticles. Responsible waste management is essential to mitigate this risk.

Safety Regulations and Guidelines

To mitigate these hazards and ensure the safe handling of Titanium Oxide Nanoparticles, various regulatory agencies and organizations have established safety regulations and guidelines. Let’s explore these measures in more detail:

1. Personal Protective Equipment (PPE)

- Respiratory Protection: When working with TiO2 nanoparticles, wear appropriate respiratory protection, such as N95 masks, to prevent inhalation. Respirators should be properly fitted to ensure effectiveness.

- Eye Protection: Use safety goggles or face shields to protect your eyes from potential splashes or airborne particles. Ensure that eye protection is compatible with other PPE, such as respirators.

- Gloves and Lab Coats: Wear gloves made of appropriate materials and lab coats to minimize skin exposure. Regularly inspect gloves for any signs of wear or damage.

2. Engineering Controls

- Ventilation: Use fume hoods or local exhaust systems to control airborne nanoparticles and ensure adequate ventilation. Ensure that these systems are regularly inspected and maintained for optimal performance.

- Containment: Handle TiO2 nanoparticles in a controlled environment such as a glovebox or isolator, to minimize the risk of particle release. These containment systems should also be routinely checked for integrity.

3. Safe Handling Practices

- Avoid Dry Handling: Minimize the generation of airborne nanoparticles by avoiding dry handling methods. Wet methods, such as suspensions or pastes, are preferred to reduce dust generation.

- Use of Safety Cabinets: When working with larger quantities, use safety cabinets or enclosures to provide an additional barrier between the nanoparticles and the operator.

4. Training and Education

- Training Programs: Ensure that all personnel handling TiO2 nanoparticles receive comprehensive training on safety procedures and protocols. Regular refresher courses should be conducted to keep employees informed of the latest safety practices.

- Stay Informed: Keep up-to-date with the latest safety guidelines and research developments in nanotechnology. Engage in ongoing education and training to remain current with best practices.

5. Waste Management

- Proper Disposal: Dispose of waste containing TiO2 nanoparticles in accordance with local regulations. Do not dispose of them in regular trash. Implement a waste disposal plan that addresses the unique characteristics of nanoparticles.

- Recycling: Consider recycling or reusing materials when possible to minimize waste generation. Implement recycling programs that are tailored to nanomaterials.

Business Involvement: SkySpring Nanomaterials

SkySpring Nanomaterials, a leading supplier of advanced nanomaterials, is deeply committed to promoting the safe use of Titanium Oxide Nanoparticles. They adhere to stringent safety standards in the production and handling of nanomaterials, setting an example for responsible nanotechnology. When sourcing TiO2 nanoparticles from SkySpring Nanomaterials, customers can have confidence in the quality and safety of the products, knowing that the company places a strong emphasis on safety.

Conclusion

Titanium Oxide Nanoparticles hold immense promise in various industries, but their safe handling should always be a top priority. Following the safety regulations and guidelines outlined in this comprehensive blog, individuals and businesses can harness the potential of TiO2 nanoparticles while ensuring the well-being of workers and the environment. Remember, safety is paramount in nanotechnology, and a proactive approach to safety is essential for realizing the benefits of this exciting field.